Cable fastening, metal band, plastic-coated steel band, tensioning band, pipe fastening

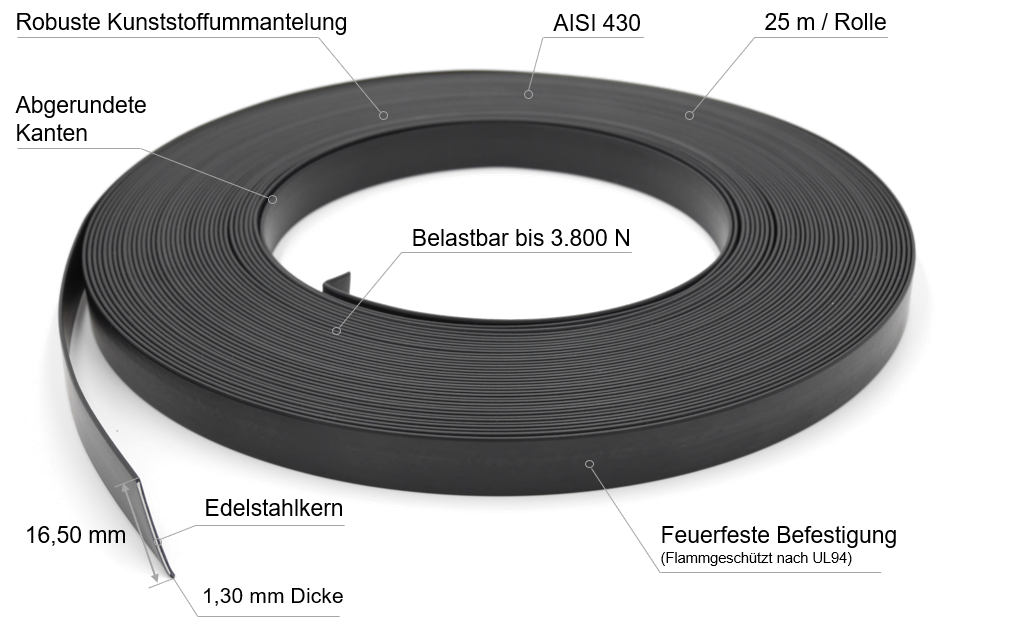

The universally applicable fastening system with plastic-coated steel tensioning straps is used for the permanent and gentle fastening of cables, lines, and pipes, for example, to appropriate supports and ducts. Following the "soft shell - hard core" principle, the plastic-coated steel tensioning strap consists of a high-strength metal core and a protective soft plastic coating. The metal band serves as a high-strength load carrier and allows for the highest mechanical loads. The high-quality and durable plastic coating protects both the metal band from corrosion and the cables and lines to be secured from cuts.

Plastic-coated steel strapping is ideal for cable and pipe fastening. The stainless steel is rustproof, fire-resistant, and of the highest quality.

Why steel band?

Depending on the requirements, the metal strap is made of rust-proof, hot-dip galvanized steel, stainless steel (V2A), or the highest-quality anti-magnetic stainless steel (V4A). These materials ensure the fastening system's maximum durability, longevity, and fire resistance. The steel strap absorbs the enormous forces when tensioning and tightening the strap. Compared to pure plastic cable ties, steel cable ties are 100 times more durable, weather-resistant, and fire-resistant.

Why plastic sheathing?

The steel tensioning strap is coated with a high-quality, flame-retardant plastic (V2 according to UL94). The plastic protects the steel strap from corrosion (weather-resistant) and mechanical influences, such as friction and scratches on supports, thus ensuring a long service life. The plastic coating of the tensioning strap also protects the cables being bundled, preventing them from cutting into cables and thus permanently reducing the risk of short circuits and the resulting fire hazard. The plastic coating of the tensioning strap also serves as thermal and electrical insulation, as required in applications particularly in the electrical sector and for pipe fastening. Additional edge or corner protectors are not required. In addition, this highly flexible plastic coating shields the user from direct contact with the steel tensioning strap, thus eliminating the risk of injury when installing the tensioning strap. Furthermore, the plastic coating, with its pleasant feel and customizable design, allows for a perfect blend with the surroundings.

V0 and hologram freedom for the highest demands

For applications requiring the highest levels of fire protection, such as in power plant construction, the energy sector, and shipbuilding, plastics with flame-retardant and self-extinguishing properties and halogen-free properties (V0 according to UL94) are used. These prevent the plastic from igniting and do not emit harmful halogens in the event of a fire.

Where is the steel tensioning strap used?

The plastic-coated steel tensioning band is mostly used as a cable tie and for permanent and vibration-free Cable fastening and pipe fastening It is used in shipbuilding, the energy, and power plant sectors and meets technical requirements regarding prescribed metallic fastenings, for example, for cables. Thanks to its protective plastic coating and durable stainless steel core, the clamping strap can be used safely even under vibration, in moving/dynamic systems, and for securing sensitive cables. This vibration resistance is achieved by the choice of a ductile and highly durable plastic. The durability of the clamping strap is designed for a service life of at least 30 years, thus enabling safe use in other areas as well.

Plastic-coated steel tape can also be used for hobby and home use

The high durability, weather resistance and longevity, coupled with the user-friendly dispenser boxes and simple attachment, enables use in the home. Be it as Cable fastening, pipe fastening or For suspending ceilings. The metal strip is also ideal for attaching signs, fire extinguishers, or other parts. It is even used as a decorative strip for furniture. There are no limits to creativity here. The visually appealing plastic coating also serves as a design element and can be used as a fastening strip, for example, for furniture coverings, in plant engineering, electrical installations, mechanical engineering, and house construction.

The steel tensioning strap is used for the professional, fast and economical assembly of additional units or system components, such as batteries, containers, etc. in the mobility sector (cars, trains, aircraft, etc.).

The Metal band is also can be used as repair tape

The plastic-coated steel tensioning strap can be used as a repair strap when damage is detected early, either indoors or outdoors. For example, if a greenhouse is in danger of collapsing due to storm damage, the weather-resistant steel tensioning strap can be used to repair it from the outside, providing increased stability. Thanks to the unique combination of metal and plastic, the repair strap is both dimensionally stable and flexible. It can therefore be bent to suit any situation.

How is plastic-coated steel strapping used?

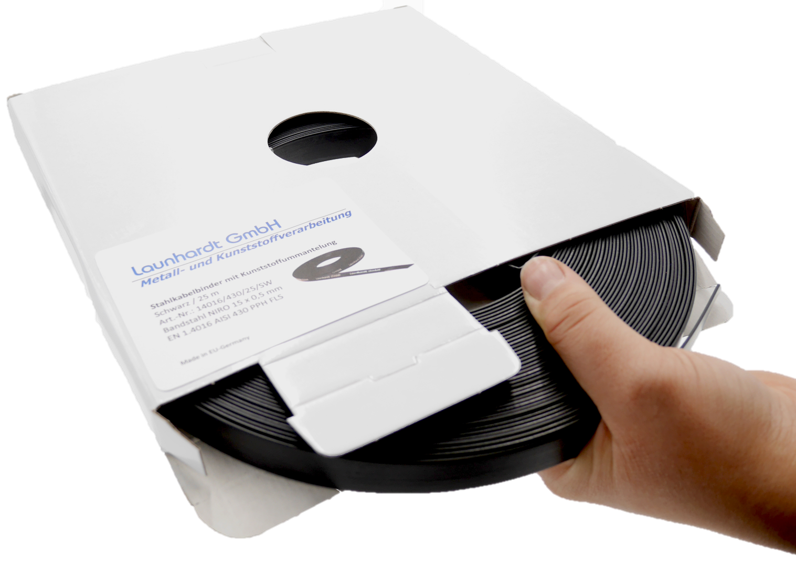

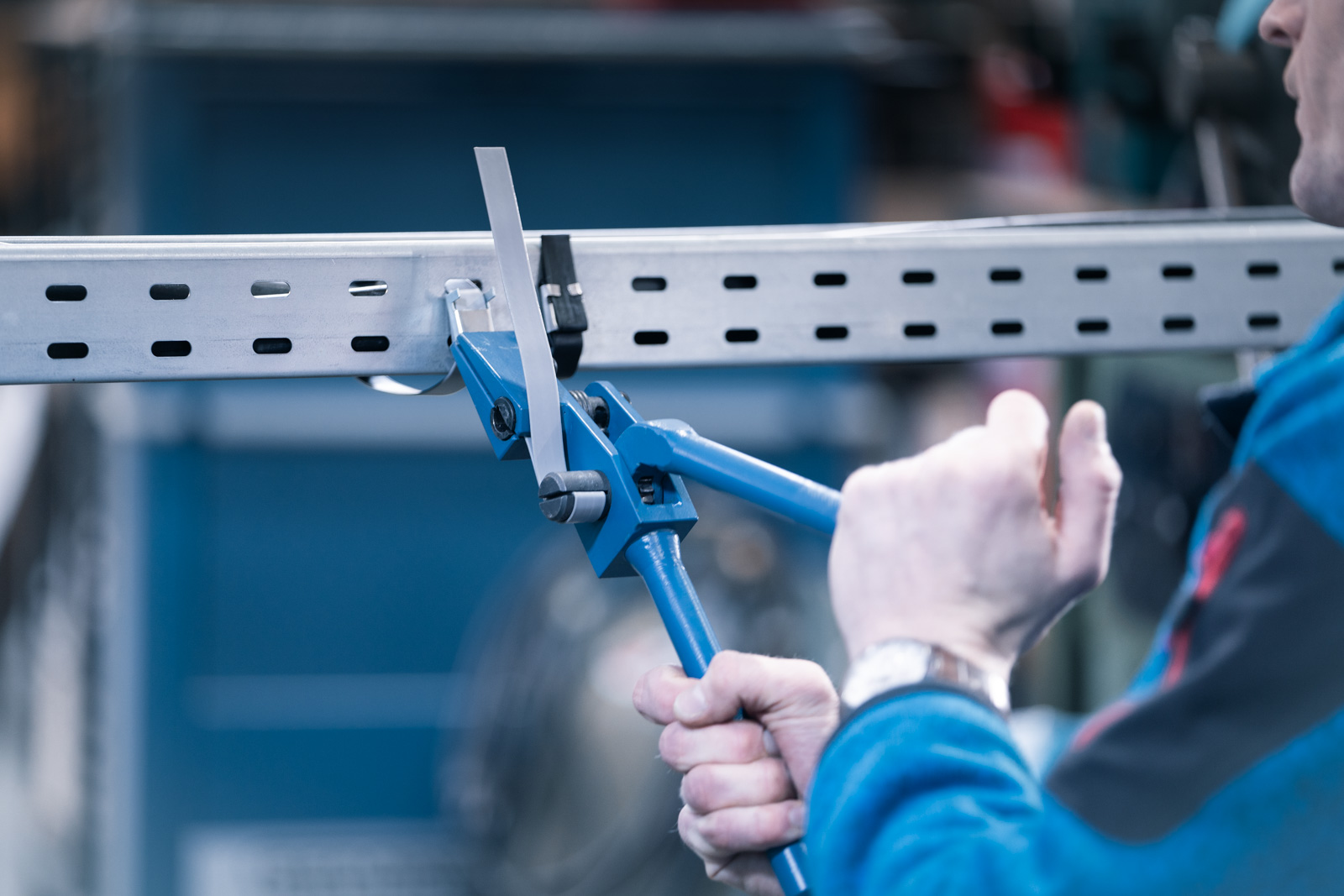

It's very easy to use. The universally applicable, plastic-coated steel tensioning strap is wound on rolls in a practical dispenser box and can be conveniently unwound to individual lengths without any excess roll unwinding. Using the special collet with integrated cutting function, the tensioning strap is cut to length and can then be pulled around the component to be tensioned. Our tried-and-tested L-clip fasteners are slipped over the strap; the strap is folded over and lashed with the collet. The strap is then bent around the robust L-clip, automatically cut off, and the L-clip tabs are bent over for permanent fixation. Alternatively, the tensioning strap can also be tensioned and secured using standard DIY tools (combination pliers, metal shears, hammer). However, with the user-friendly collet with integrated cutting function, this can be done much faster and more conveniently.

Plastic-coated steel band in a practical and user-friendly dispenser box.

What variants of the metal band are there?

The plastic-coated steel tensioning strap is available in widths of 16.50 and 9.00 mm. Packaged in convenient dispenser boxes, the steel tensioning strap can be cut to individual lengths without waste. Common bundles consist of 100 or 300 m of tensioning strap, a special tensioning strap pliers (with cutting function), and 500 or 1,000 L-clip locks.

Available in various sets with accessories for assembly

1 x collet (wide)

500 x L-clip locks

- fit the respective tensioning strap

- Stainless steel, 1.4016, black

(AISI 430)

- Antimagnetic, 1.4401, 1.4404, 1.4571, brown, (AISI 316 T (Ti, L))

- Hot-dip galvanized, 1.0226, grey

- Stainless steel, 1.4016, black

(AISI 430) - Antimagnetic, 1.4401, 1.4404, 1.4571, brown, (AISI 316 T (Ti, L))