very soft TPU powder, SLS components made of TPU, Shore hardness 55, 3D printing with TPU

Very soft TPU powder; rubber-elastic 3D components, Shore hardness 55

Thanks to an innovative manufacturing process and a novel post-treatment of the SLS powder, we are able to provide extremely soft TPU powders for the SLS process. Compared to plastic powders from competitors, our TPU SLS powder offers the following key advantages:

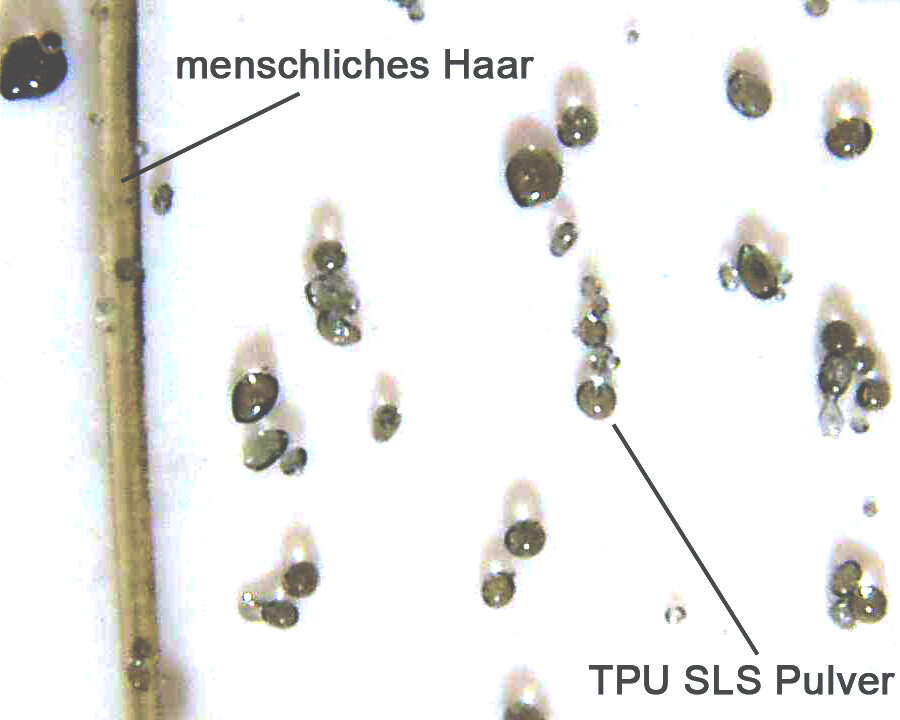

- Spherical particle shape

- Narrow particle size distribution, D[V, 90] = 96 µm

- Optimized flowability

- No smoke development during processing

- 100 reusable

- Very soft material behavior (Shore hardness A 55)

- Pleasant feel

- Elongation at break of at least 450 %

- Hydrolysis resistant

- UV-resistant

- White or black components possible

The soft thermoplastic polyurethane powder for the SLS process features spherical particle shapes, ensuring optimal flowability. Unlike many other SLS TPU powders, it does not emit fumes during processing, which could impair the system. This means that no modifications or complex cleaning of existing SLS systems are necessary. Since the material does not age significantly due to thermal degradation, our TPU SLS powder is 100% reusable, which offers significant economic and ecological benefits. The very soft TPU SLS material offers a very pleasant feel, making it ideal for applications in the orthopedic sector, for wristbands, or production aids. The rubber-like properties, with an elongation at break of at least 450%, are comparable to injection-molded TPU components. Furthermore, the SLS TPU component is hydrolysis-free and therefore washable up to 60°C and UV-resistant. For use in low-performance SLS systems, we offer the absorption-optimized TPU in black.

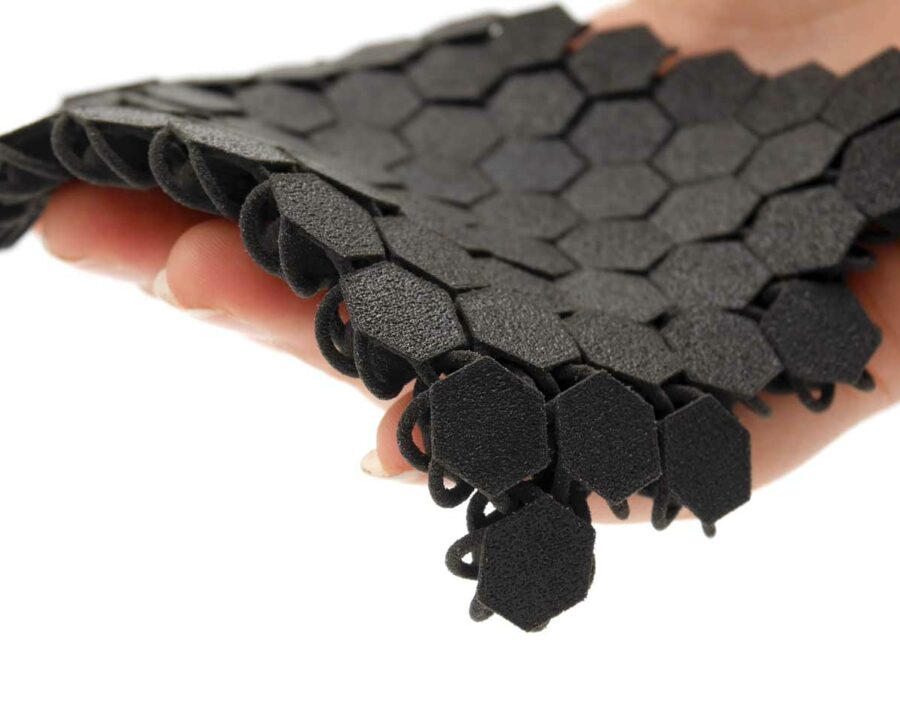

3D printing with TPU: Soft TPU for bracelets, shoe soles, etc., here as elastic chainmail with a pleasant feel.

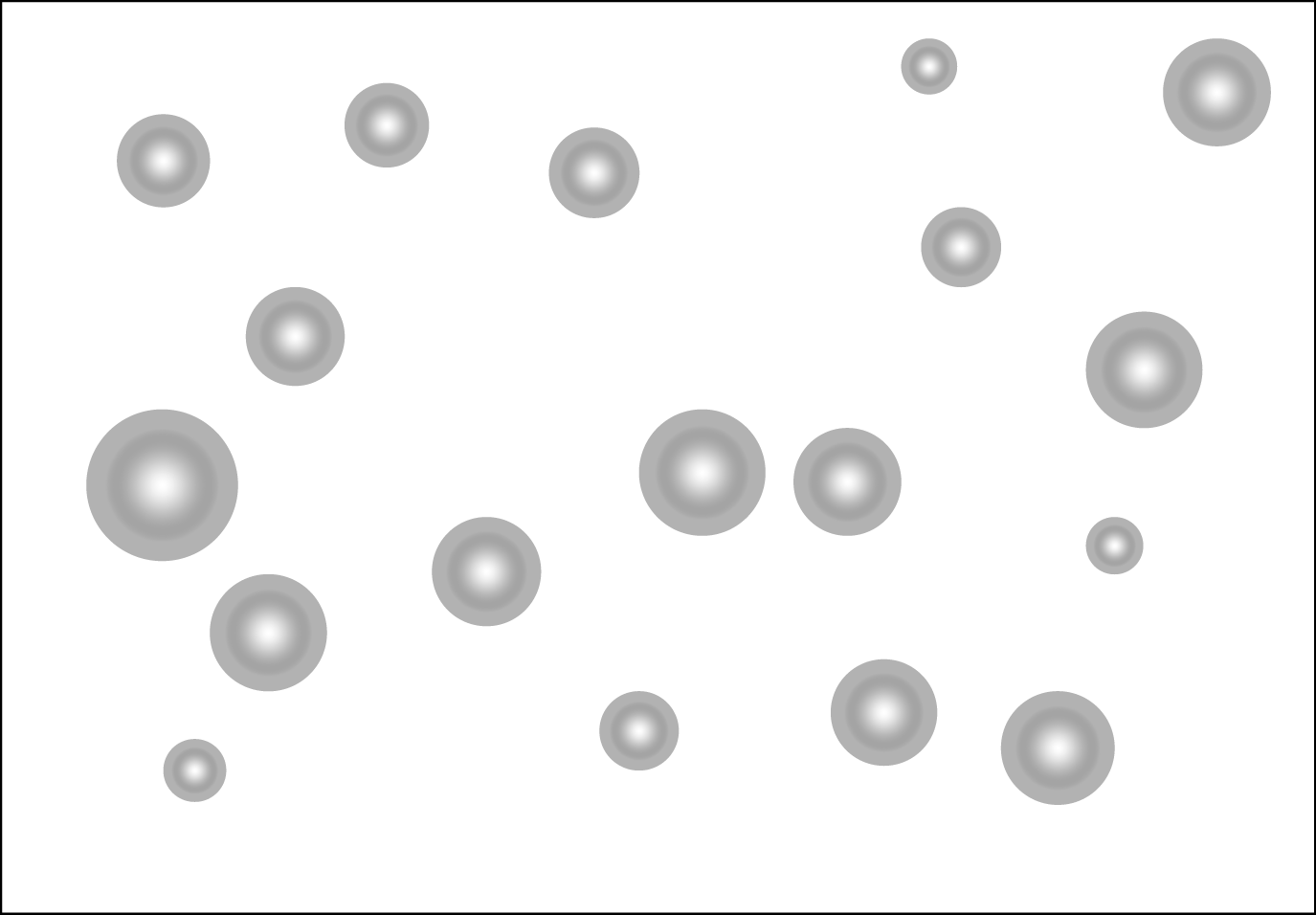

Close-up of spherical TPU powder particles in size comparison to a human hair.

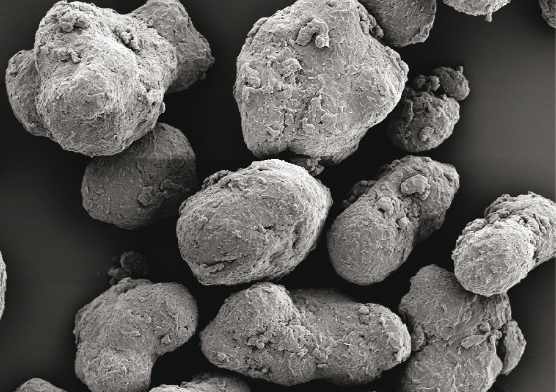

Polyamide 12 as an established material for the SLS process

While polyamide 12 powder (PA12), which is already spherical due to its production, has become the main material of choice for selective laser sintering (LS, SLS), more and more new and alternative materials for SLS are currently entering the market. During a chemical precipitation process, polyamide 12 polymerizes into bean-like particles. With a particle size distribution of D[V, 90] = 88 µm, PA12 is particularly well-suited for a layer-by-layer additive manufacturing process with a layer thickness of 100 µm. A disadvantage of PA12 is the thermo-oxidative aging of the plastic. For this reason, this powder usually needs to be refreshed to 50 wt. %.

Complex PA12 component as lampshade with complex design elements [Designed by Roman Rainer Schmid, www.romanreiner.com]

Close-up of PA12 SLS powder with typical potato or bean-like particle shape.

What about rubber-elastic materials for the SLS process?

Thermoplastic polyurethanes (TPUs) represent a very interesting group of thermoplastic materials that exhibit rubber-like properties when injected. Depending on their chemical composition, TPUs can vary from very hard to very soft. Hard TPU grades with a Shore A hardness of 90 have been established for SLS processing. Soft TPU SLS powder has not been possible until now.

Example of a hard TPU SLS powder: Application as a finely structured shoe sole/midsole made from 3D printing with TPU.

TPU grades with high Shore A hardnesses (e.g., 80-90) are well suited for thin structures whose fine geometry enables "soft" kinematics. SLS components made of TPU with high Shore hardness are already widely used for shoe soles, midsoles, seals, and similar applications. However, if the available space or a soft feel is desired, hard TPUs are not an option.

Why is there no very soft TPU powder for selective laser sintering?

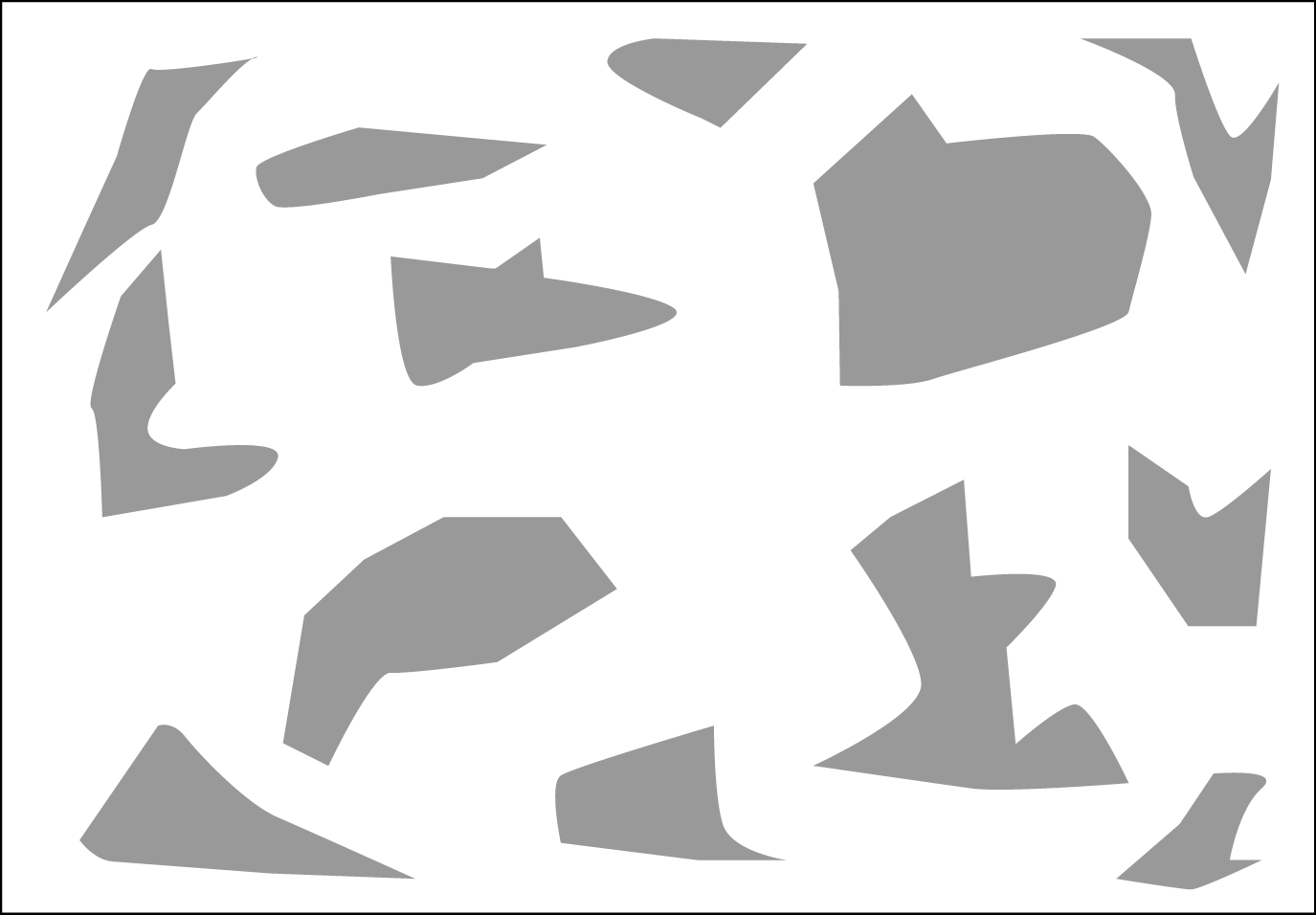

In conventional powder production, a certain rigidity and hardness of the base material is necessary to form a defined particle shape. The TPU is cooled down using liquid nitrogen to grind it. This method makes it possible to produce elastomer powder from TPU with Shore hardnesses of approximately 80 and higher, with the powder particles exhibiting a very angular shape. With softer TPU (e.g., Shore hardness 55), such grinding was previously not possible.

Schematic representation of the powder particle shape as it is produced during cryogenic grinding of TPU with high Shore hardness.

Schematic representation of the powder particle shape of our soft TPU SLS powder. The spherical shape enables optimal flow and powder deposition properties (Shore hardness 55). The spherical shape enables optimal flow and powder deposition properties in the SLS process.

Very soft TPU powder, what can be done with it?

The SLS process enables the production of highly complex structures without the need for support structures. This makes it possible to 3D print not only interesting design elements but also entire textile structures with TPU. At the same time, an SLS component made of soft TPU feels very pleasant on the skin. Orthopedic insoles, shoe soles, and jewelry are just as possible as the 3D production of technical shock absorbers, TPU seals, and other SLS components made of TPU.

Possible SLS components in 3D printing with TPU:

- 3D-structured TPU shoe soles

- Complex 3D midsoles made of TPU

- Orthopedically customized TPU insoles

- TPU wristbands for production aids

- TPU damping elements

- System feet made of TPU

- Textiles made of TPU mesh

We research and develop the implementation of the process capability of soft TPU's for the SLS process

Since each material in the SLS process requires very fine parameter adjustment with regard to laser power, exposure parameters, process temperature and much more, we research and develop suitable process parameters and optimal powder compositions in order to make the soft TPU material optimally accessible to the selective laser sintering process.

We would be happy to work with you to investigate the possibilities of developing a suitable material for your SLS system so that you too can produce SLS components from very soft TPU.