New DyeMansion PowerShot S for post-processing of 3D printed parts

DyeMansion PowerShot S, 3D printing post-processing, automated 3D printing, smoothing of SLS parts

The quality requirements for 3D-printed parts are constantly increasing. Even if 3D printing cannot be directly compared to the established, series-ready injection molding process, the industrial and pre-series use of 3D printing technologies requires that 3D-printed parts be approximately comparable in quality to injection-molded components.

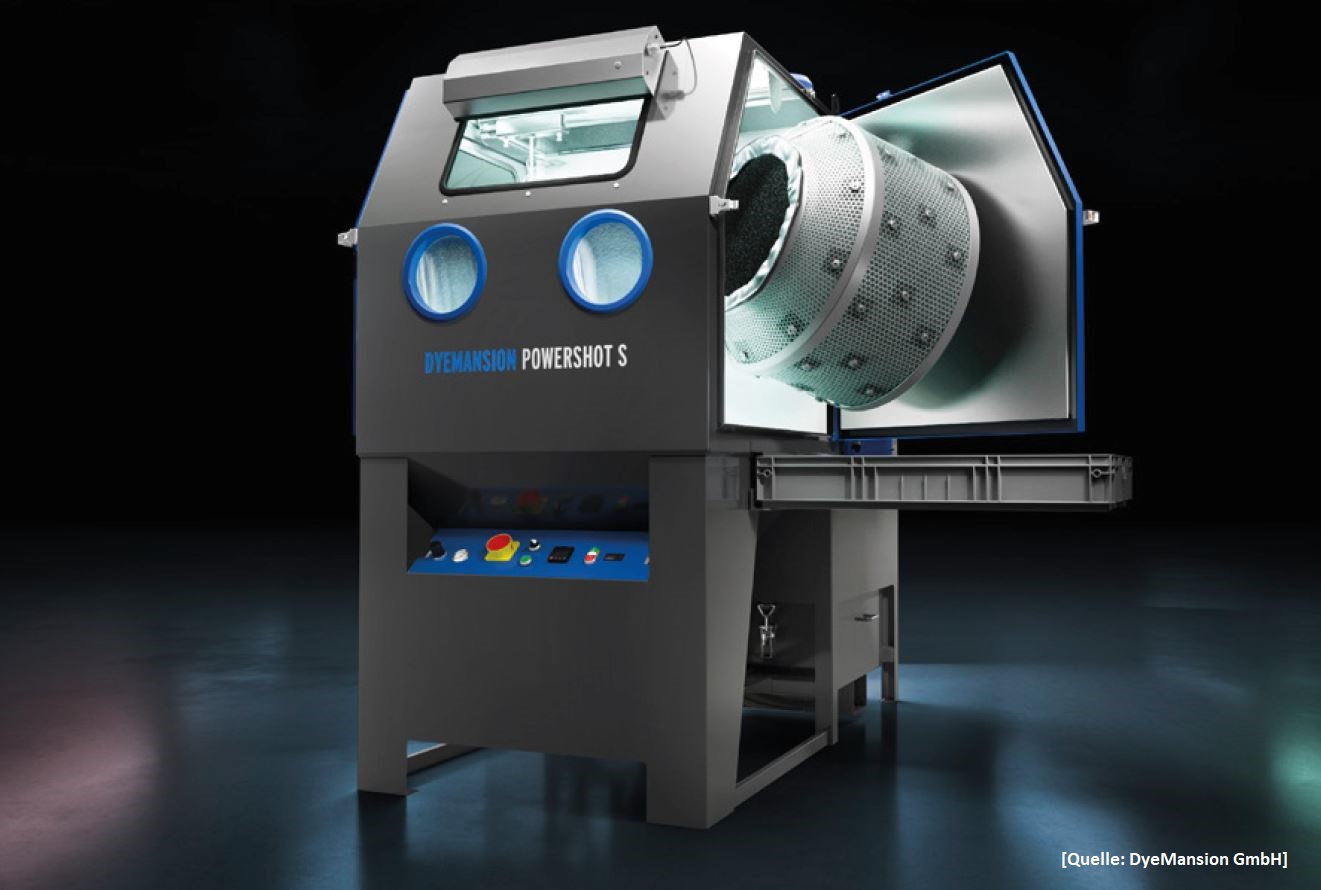

For this reason, Launhardt GmbH has expanded its portfolio for industrial smoothing of SLS components with a professional jet smoothing system. Using a PowerShot S from DyeMansion, we are able to significantly smooth and densify the surface roughness characteristic of selective laser sintering. This not only enables a pleasant tactile feel for the components, but also significantly improves the visual appearance of the SLS components.

The advantages of this post-processing are particularly evident for colored SLS components. Smoothed SLS components exhibit a distinct shine and significantly richer colors than unsmoothed components. Compared to vibratory finishing, shot blasting offers the advantage of smoothing the components from all sides, even in hard-to-reach areas such as undercuts and sharp edges.

New post-processing system for automated jet smoothing of SLS components, PowerShot S from DyeMansion.

Are you interested in professional 3D-printed components with smooth surfaces and rich colors? Then contact us. We would be happy to discuss your project idea with you and offer you a suitable solution.