Collaboration with Voxeljet and Fraunhofer IPA within the Material Network

Launhardt, Soft TPU on HSS, industrial 3D printing

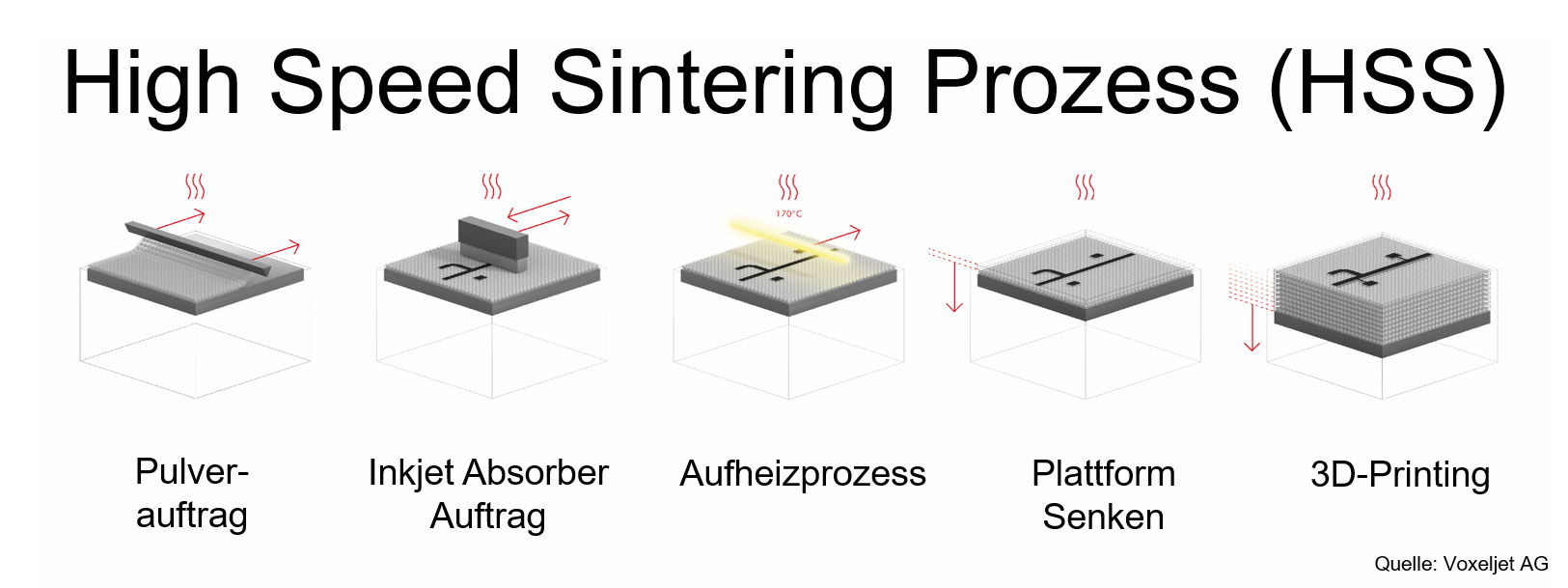

The High Speed Sintering (HSS) process represents a new type of industrial 3D printing. This powder-based additive manufacturing process does not require a laser or a scanner. This eliminates two production time-limiting factors, resulting in consistently fast production times.

In the HSS process, the powder material is printed with an absorbent ink and then exposed to an IR lamp and melted.

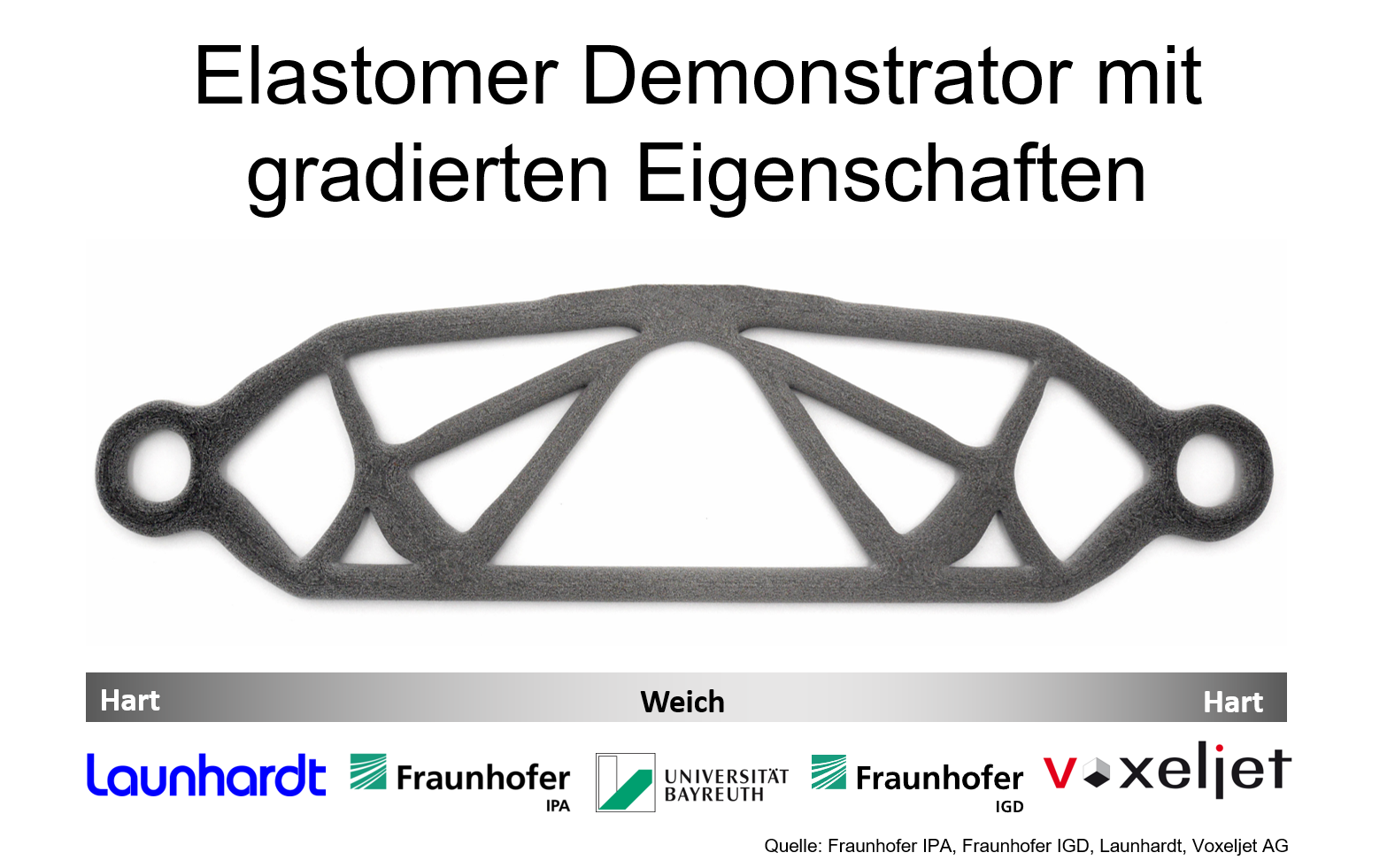

In particular, our very soft and elastic 3D printing material (TPU Soft) is particularly well-suited for processing in the HSS process, as the heat energy required for melting can be better absorbed. This allows for the creation of very fine and, above all, graded hardness properties.

This allows Shore A hardnesses between 50 and 75 to be achieved within a single build space and within a single component. This opens up entirely new possibilities in the field of 3D printing of elastomer components. For example, lattice structures, seat and back cushions, shoe soles, or seals and dampers with entirely new properties can be realized.

Elastomer component made of Launhardt TPU Soft with defined Shore hardness; soft on the left and hard on the right; manufactured using the HSS process at Fraunhofer IPA.

Under load, this TPU component demonstrates the possibilities that can be realized with defined and graded material properties.

You can find out more about the HSS process and Voxeljet’s system technology here

https://www.voxeljet.de/industrielle-3d-drucker/prototyping/vx200/

Voxeljet, HSS system VX200

If you want to process soft TPU material, just contact us here

http://launhardtgmbh.de/anfrage/

More about the collaboration between Launhardt, Voxeljet and Fraunhofer IPA can be found here