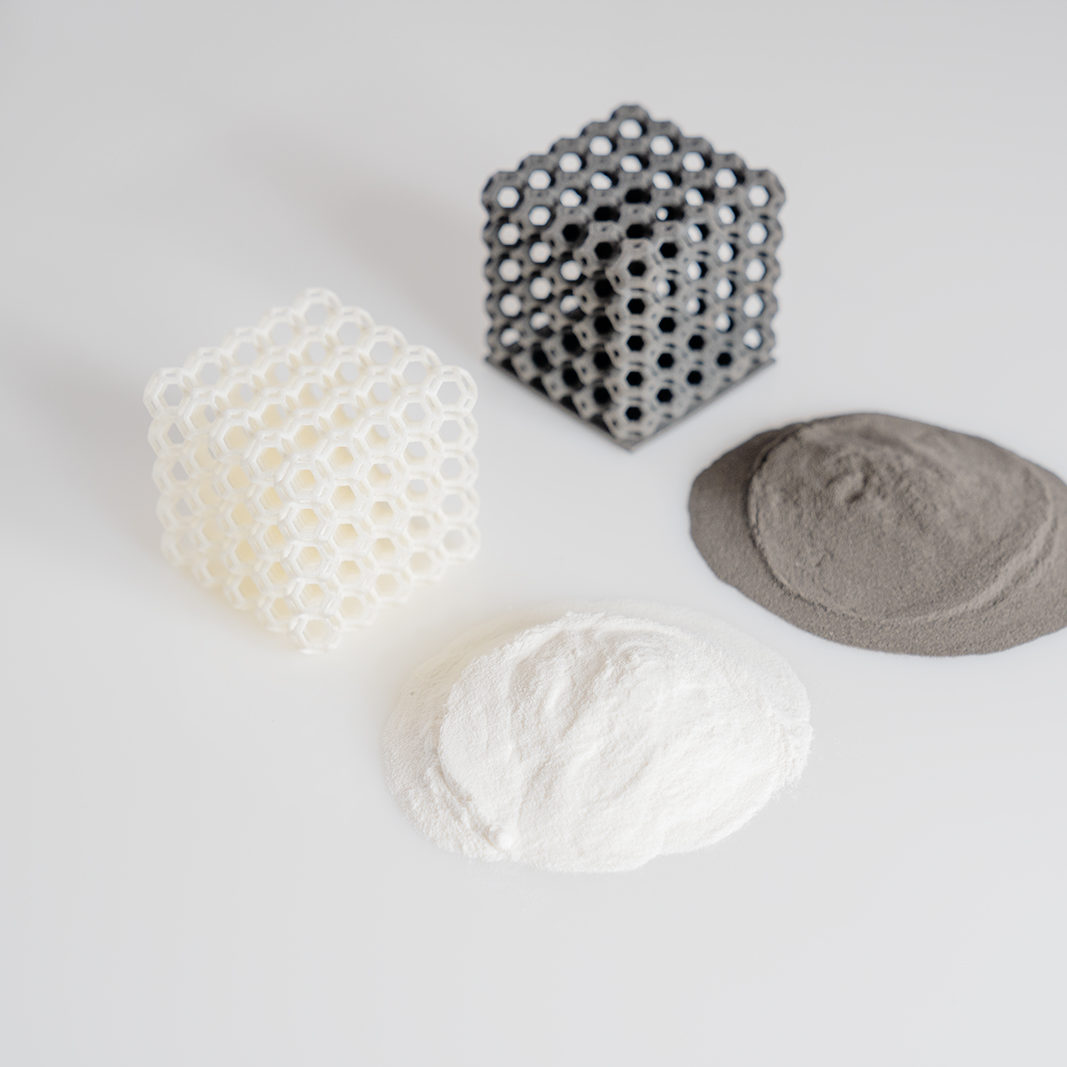

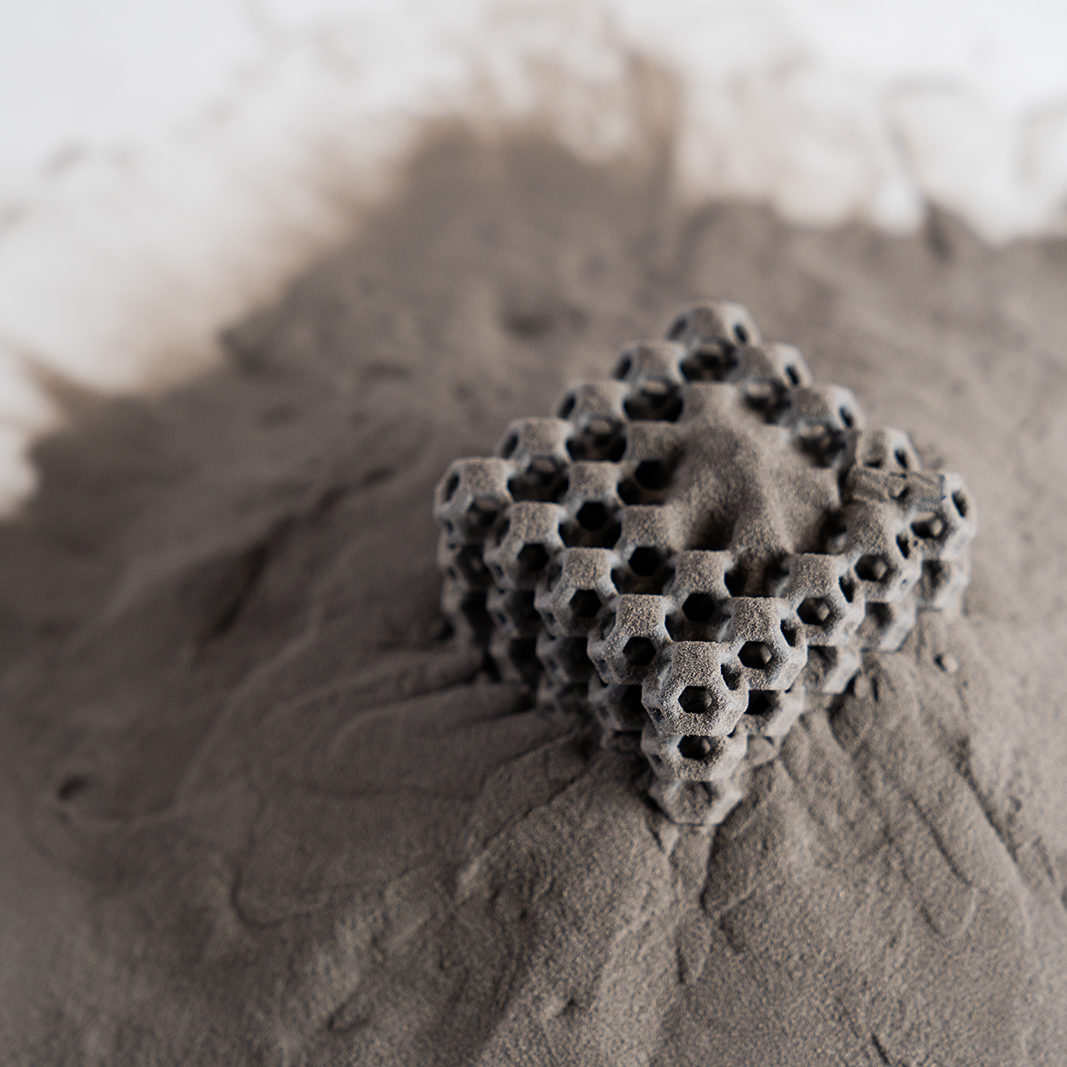

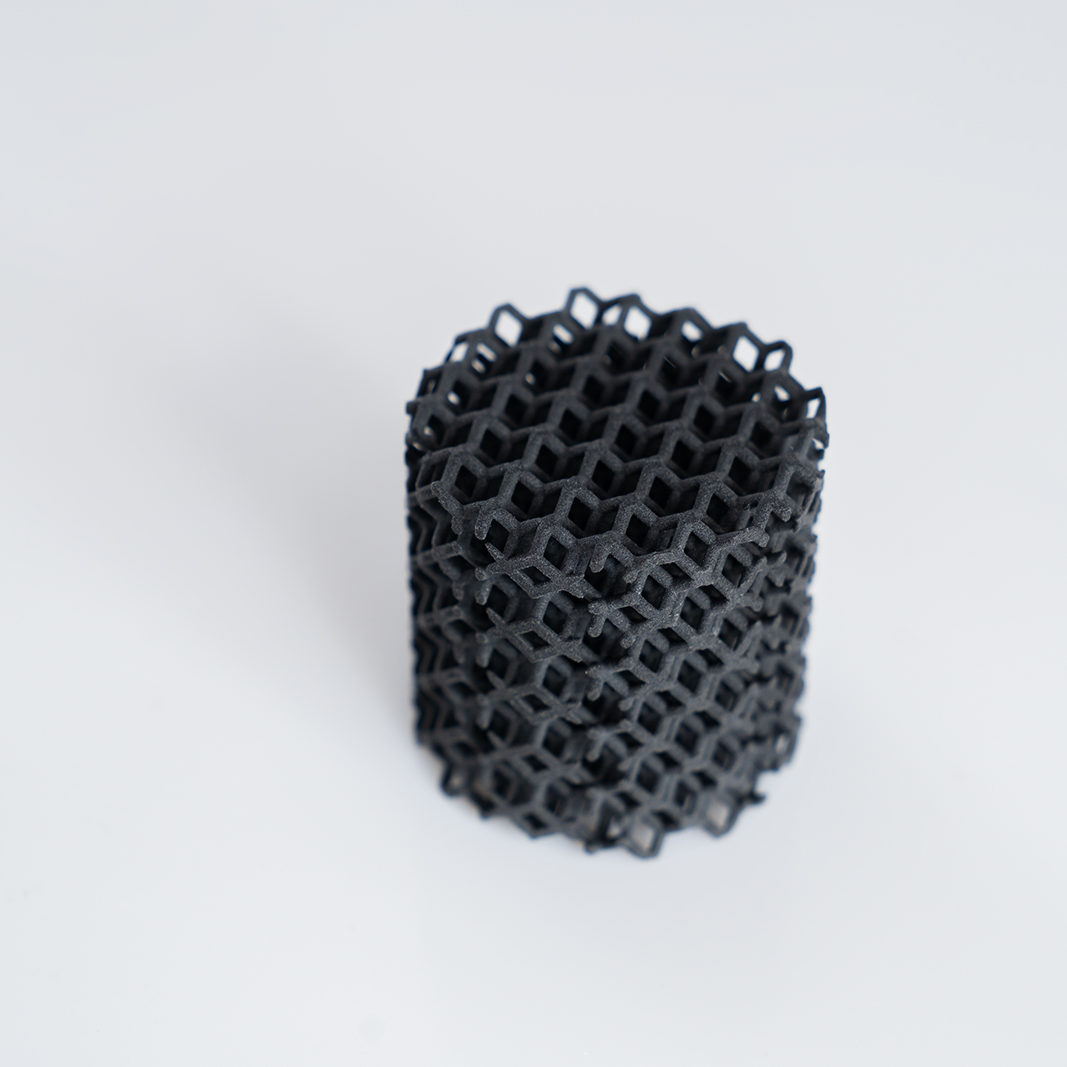

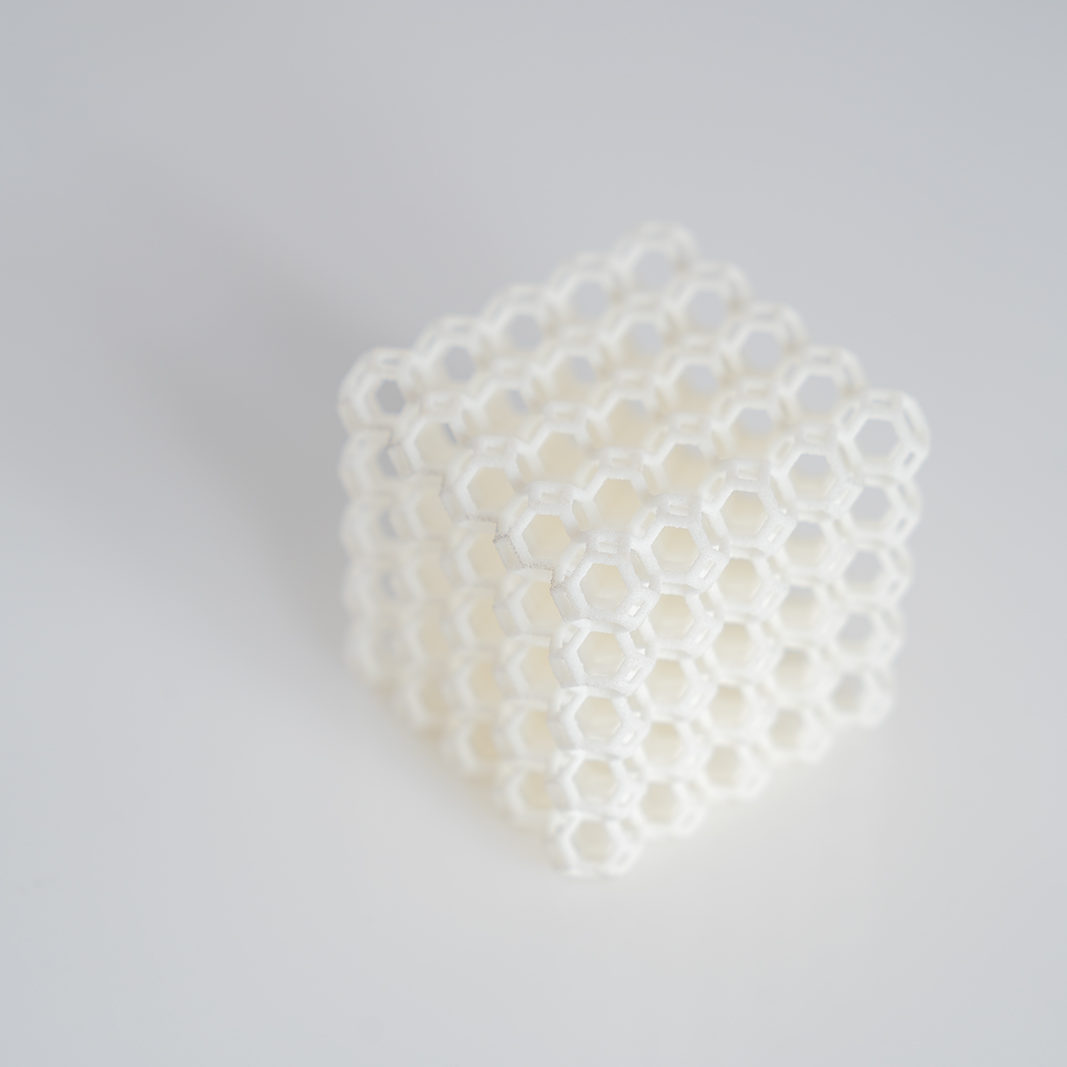

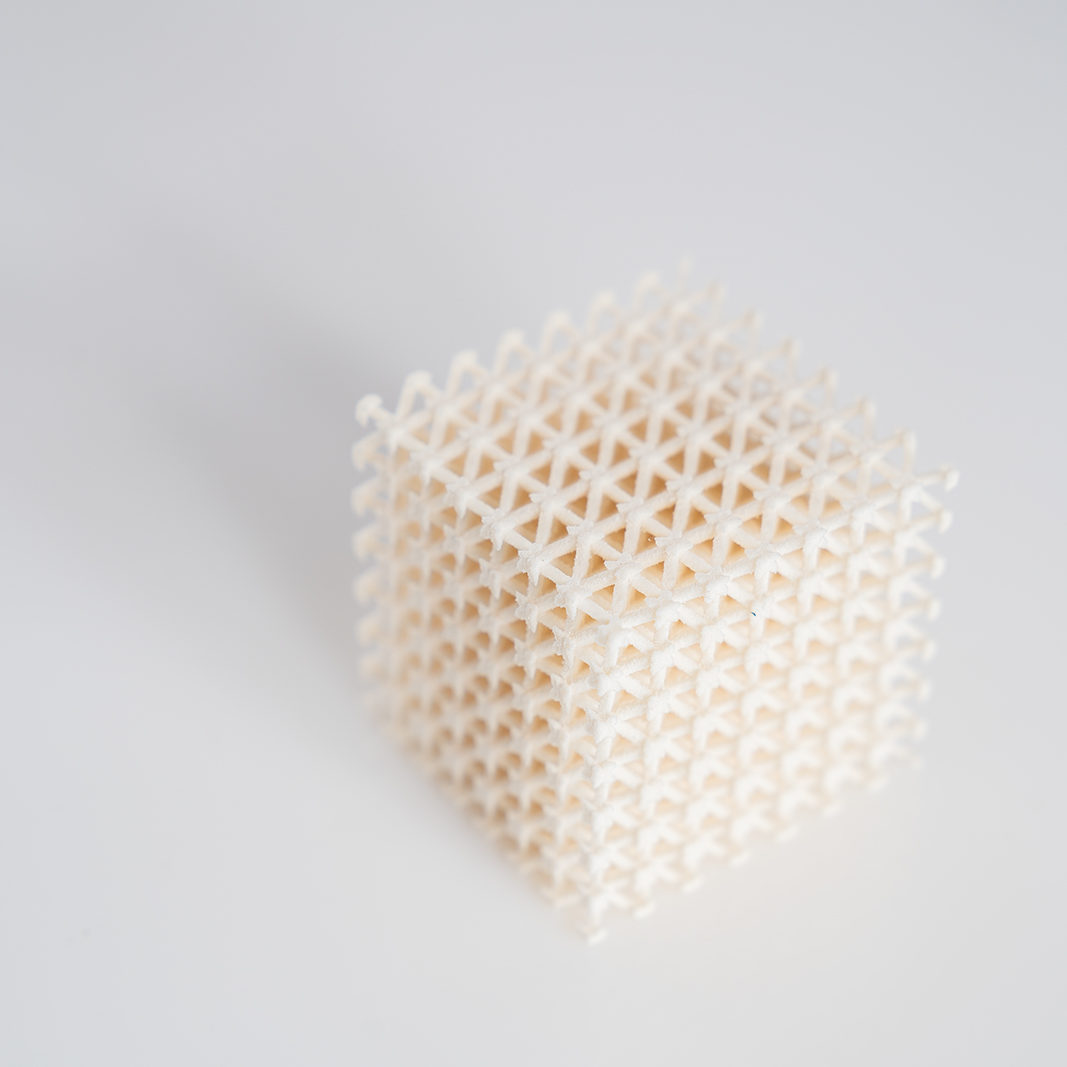

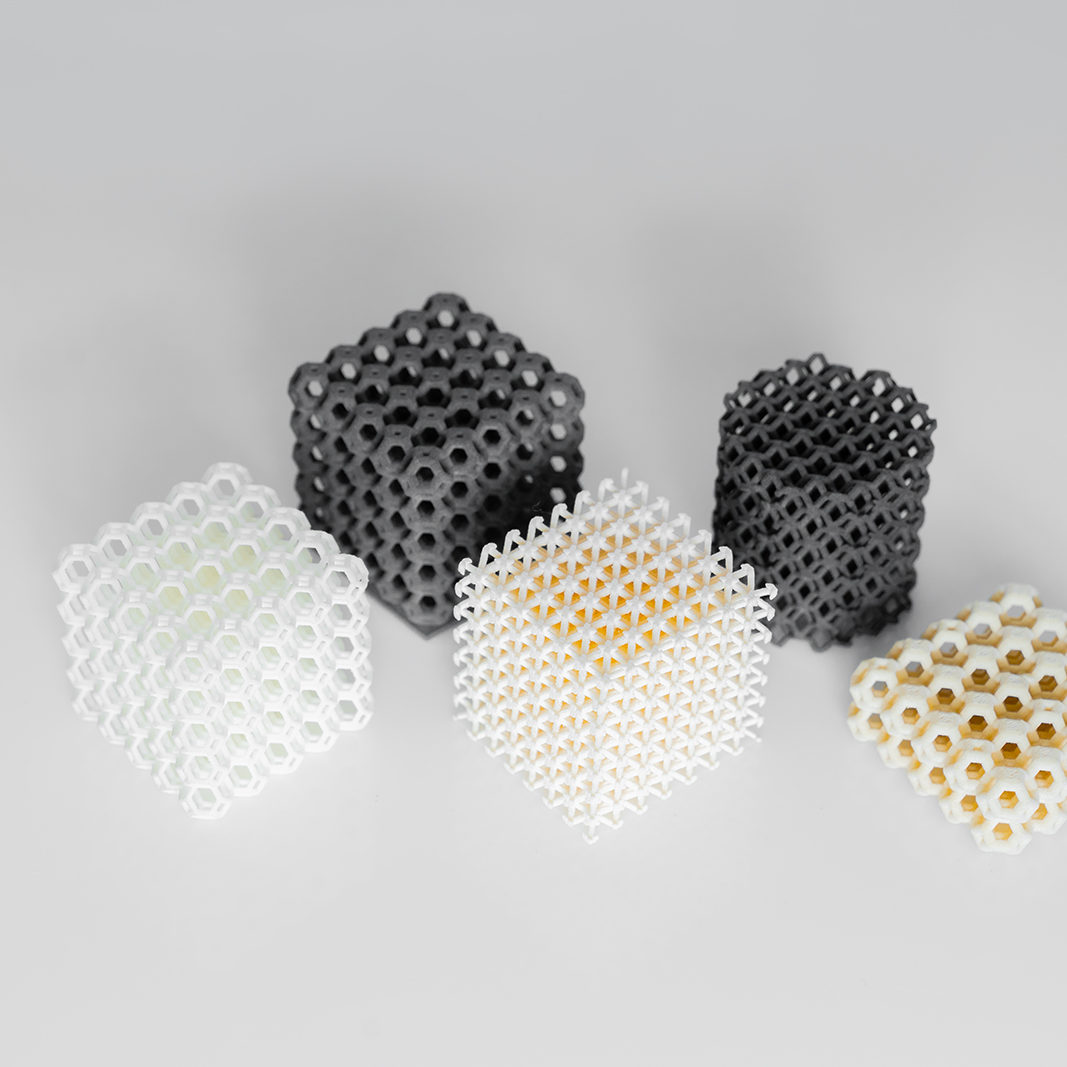

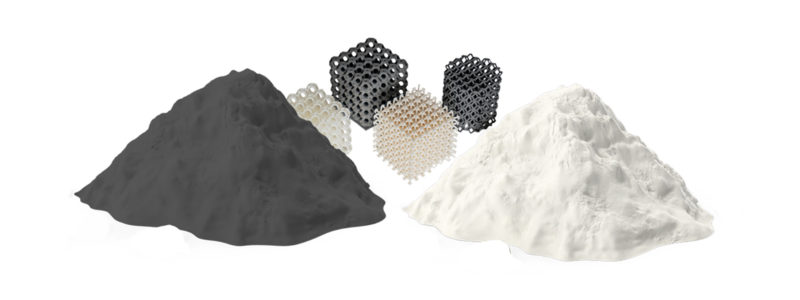

In selective laser sintering (LS), fine thermoplastic powder is melted layer by layer using a CO² laser to produce complex three-dimensional components with high mechanical properties. PA12 has become the dominant material for this process. Alternative thermoplastics are rarely available in sufficient quantities. Powder flowability and the resulting component properties in the LS process depend primarily on the particle shape. For this reason, a high degree of sphericity of the individual powder particles is beneficial. Conventional powder production processes are particularly inadequate for ductile and tough materials. For this reason, we offer the materials polypropylene (PP) and urethane-based thermoplastic elastomers (TPU) as powders for the LS sector with highly spherical particles.

Additive manufacturing / 3D printing

Prototypes

Technical components

Design models e.g. lamp design

Spare parts

shoe soles

Model making

Complex structures

Areas of application

Selective laser sintering (LS) of plastics requires extremely fine powder with spherical particles and the highest possible packing density. For this reason, we offer these optimized PP and TPU powders for the LS process.

The components manufactured in this way are used both as prototypes and as directly usable components, design and advertising elements, orthopedic and patient-adapted insoles and, for example, as cost-effective spare parts.

Technical data

LS powder materials

- Thermoplastic polyurethane, TPU, hard (Shore A 85), natural;

- Thermoplastic polyurethane, TPU, soft (Shore A 60), natural;

- Polypropylene, PP, black

-

-

Tensile strength

- TPU hard: 28.0 MPa

- TPU soft: 5.5 MPa

- PP: 25.0 MPa

Elongation at break

- TPU hard: 250%

- TPU soft: 450%

- PP: 30%

Reusability

- TPU hard: 100%

- TPU soft: 100%

- PP: 100%

Refresh rate

Only the amount of powder that is removed as finished components

~ 10 wt.-%

We supply you with your customized 3D printing powder

Adapted to your powder-based additive manufacturing process, we offer powders made from a wide range of thermoplastics specifically tailored to your application. Their high particle sphericity and defined particle size distribution provide excellent flow and processing properties.

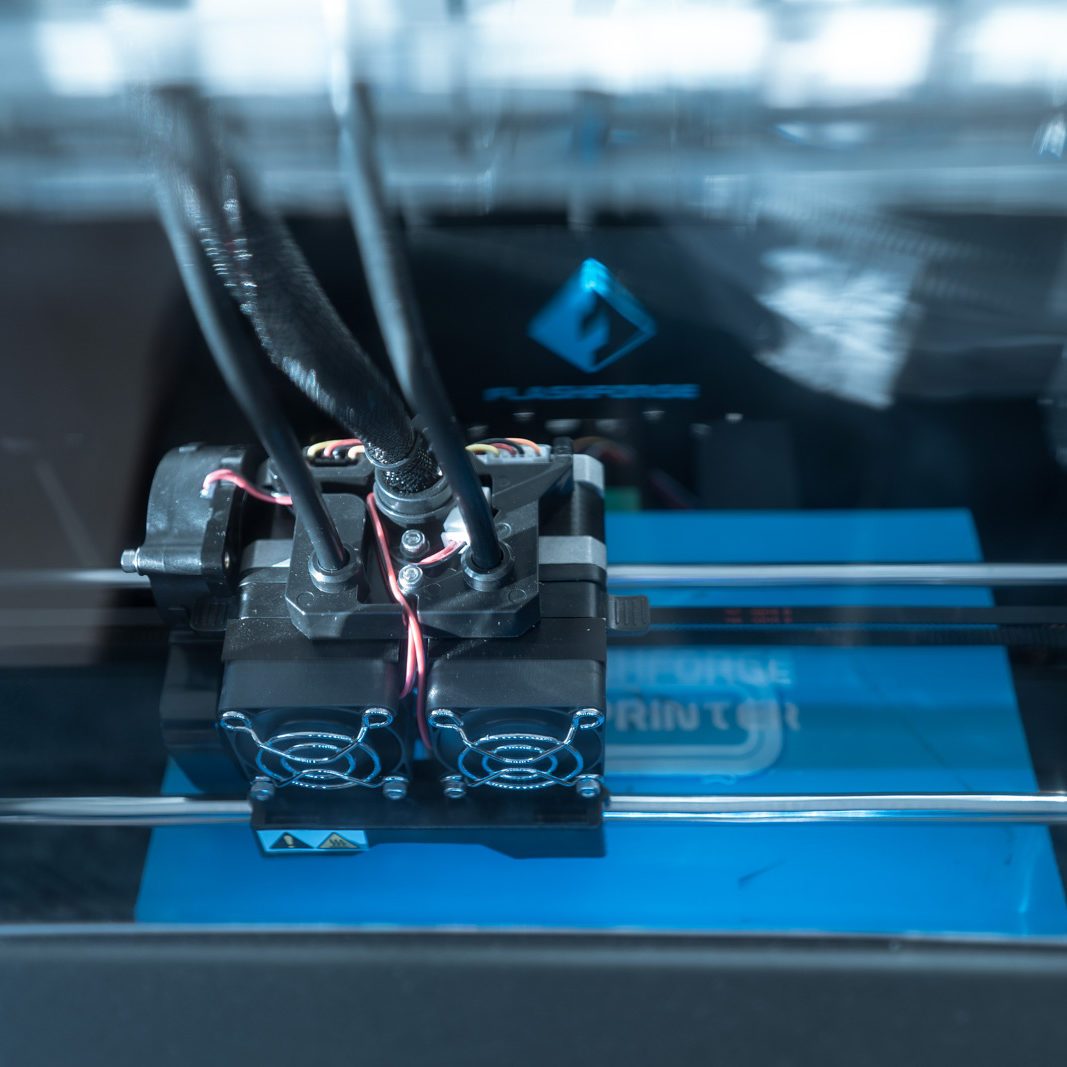

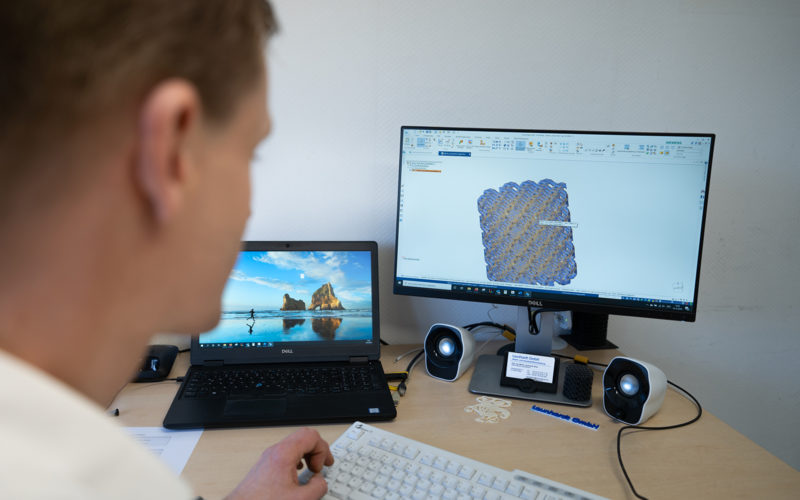

We develop the best processing and process parameters for you

Every LS system is different and requires different process parameters to achieve the highest possible component properties. Together with our LS powders, we offer customized process parameters and optimize them for your application.

We manufacture your 3D components

For small and small series, we offer the option of having your CAD components and geometries manufactured directly by us. With downstream quality control regarding dimensional and form accuracy, as well as compliance with mechanical and optical properties, we offer you the highest quality economically, quickly, and flexibly.